Tech Talk

Hydropavers International is the leader in permeable paving solutions. Our team of experts is available to consult with specifiers and installers on all aspects of permeable paving projects. Premier Hydropavers® and Meteor Interlockers® have been tested in all paver requirements to ensure that they have the structural integrity and the breaking load capacity to comply with all Australian standards and cope with the most severe traffic loads.

The long-term performance of your project is determined by the quality of the work that’s done to prepare the base below your pavers and walls. A proper base will ensure that your pavers won’t settle or shift out of place.

Strength and Durability

Premier ceramic Hydropavers® and concrete interlocking Meteor Interlockers® have a breaking load strength, irrespective of size ranging from 10 kN to 20 kN (1-2 tonnes) and a compressive strength of 50 Mpa making them suitable for all types of traffic from heavy commercial vehicles to pedestrian areas. (See data sheets in resources.)

Applications

Premier Hydropavers® and Meteor Interlockers® are suitable for a wide range of applications. From residential to commercial and pedestrian to vehicular. Premier Hydropavers® and Meteor Interlockers® have been tested in all necessary categories of paver characteristics to ensure that they are applicable and appropriate for all permeable segmental paved areas. (See data sheet for testing details.)

Installation

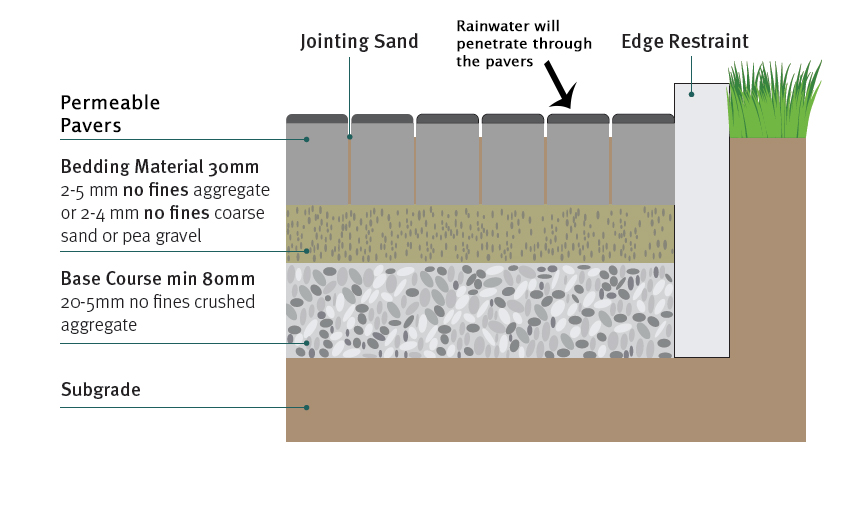

The installation process and the use of the correct materials when installing Premier Hydropavers® and Meteor Interlockers® is essential to achieving the final goal. Below is a detailed diagram of how to install Premier Hydropavers® and Meteor Interlockers®. (See the Premier Permeable Paving Solutions technical manual for more information).

The first step in any project is the excavation of grass and topsoil.

The depth will depend on two factors:

- Soil Type – Clay soil requires deeper excavation; sandy soil requires less.

- Use – Heavy loads like driveways require deeper excavation; lighter loads like patios and walkways require less.

The excavated area will be filled with base gravel. This gravel base needs to be:

- Strong enough to handle the load of whatever is placed on the surface.

- Free draining so that water drains out of the base into the subsoil.

- Extended at least six inches beyond the edges of the finished paver surface.

- Compacted in several layers, using the proper equipment.

The right bedding material installed at the right depth is vital to the performance of your pavement. It provides a nice smooth surface for laying pavers and allows water to quickly drain away from the surface.

An edge restraint secured with long metal spikes will prevent the perimeter pavers from drifting away from the edge.

Joint material plays an important role in further locking the pavers in place, as well as keeping weeds and other debris out.

Maintenance

Premier Hydropavers® and Meteor Interlockers® permeable paving systems are easy to maintain and require the same maintenance schedule as any other form of flexible segmental pavements. Due to the unique characteristics of water infiltrating through the body of the paver there is no need to constantly clean or replace course jointing material. The sand filled joints may require initial topping up until they consolidate via natural weathering processes. Once this is achieved the paving can be swept and maintained in the same way as any other flexible segmental pavement.